|

CopperPoxy - 11 year report Bottom

paint is often a discussion item among all boaters. From what we hear

around the docks and anchorages, bottom paints/coatings/systems are

about the second topic to come up. The first is anchors and anchoring

techniques, and that takes on heated discussions similar to ones

involving politics or religion.

It

seems everyone has a brand or type that works for them. We are no

different in that regard. We know that one type of paint might work

very well in the Pacific Northwest and not at all in tropical

waters.

We

have used a number of different bottom paints over the years and have

found most to perform as advertised. That is, they stopped hard

growth off of the bottom of the boat for a year or two. Some worked

better than others. ALL have positive points, and ALL have bad

aspects to them.

Originally

I was not going to write up this report as I thought no one would be

interested. Also, it seems that you can no longer get CopperPoxy from

our original source, AMC. However, I have recently seen a number of

threads on sailing and cruising message boards asking or talking

about copper bottom products. After using the product on our cruising

sail boat from the San Francisco Bay, down the West coast to Cabo San

Lucas Mexico, and up into the Sea of Cortez, I think I can speak to

how it has worked for us.

PLEASE

UNDERSTAND, this is OUR experience with the product

called CopperPoxy.

We

make NO claims that it will work for any one else as it has for us.

Having said that, we have photos to document all of our findings.

CopperPoxy

is a mixture of about 40% epoxy and 60% pure copper powder. The

copper powder in the mix we purchased was said to be 10 mil spheres.

When applied to the bottom of our boat, it was to act as a bottom

anti fouling coating and a barrier coat as well. It also made the

bottom look like a shinny new penny.

In

October of 1996, we applied CopperPoxy to the bottom of our Nor'Sea

27. We were in the San Francisco Bay area at the time. From the time

we dropped her back in the water we were living aboard.

When

we decided to try the CopperPoxy we were warned by MANY well meaning

friends that it was just a lot of huey, snake oil, junk science. It

seemed that everyone had something to say about the product. And very

few had anything good to say. A number of people backed their

negative comments with what seemed to be somewhat logical

explanations.

We

thought long and hard, but decided to take the chance. We have read

that in the past, when ships were made of wood, many used to cover

the bottom with copper plates. It seemed to me that we would be doing

something similar. Also, at that time the cost of the CopperPoxy was

about 30% higher than the normal bottom paint we were using. So, if

it only lasted 2 or 3 years, it would STILL be less expensive. Not

having to do even one extra haul out, with all the associated costs,

would more than make up the small difference in the cost of the

covering. If you look at the total cost for a bottom job, the paint

is only a small part.

If

you have read our past reports you know we had to remove ALL old

bottom paint before we could apply it. That was a lot of work.

After

we applied it, we dropped back in the water. We waited one year, and

then had a diver carefully inspect the bottom. We then posted a “one

year report” on it. Almost one year after that, we did a haul out

to touch-up some areas that we did not do correctly the first time.

This

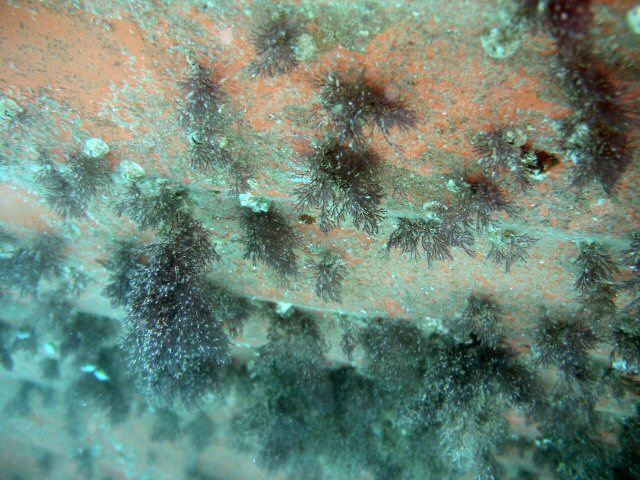

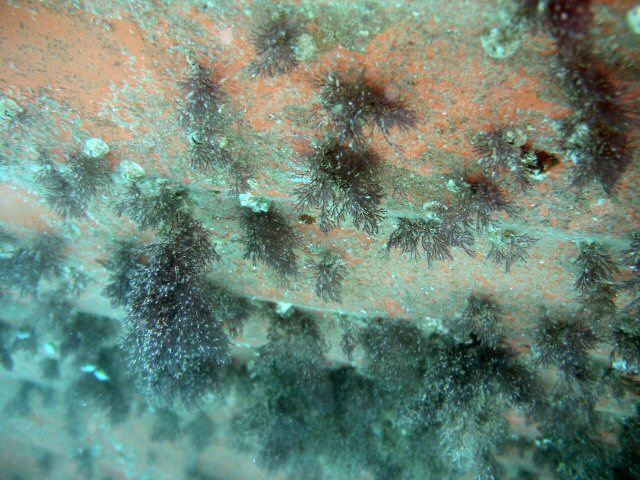

is a photo of the bottom, still wet as we hauled out after 2 years. This

is a photo of the bottom, still wet as we hauled out after 2 years.

You can make up your own mind as to how well it worked as you look at

the photo.

We

then spent the next next 6 years sailing in and out of a marina in

Redwood City, and Oyster Cove marina, all in the San Francisco Bay

area.

In

September of 2004 we hauled out at Svendsen's boat yard on Alameda

Island, and touched up some of the CopperPoxy. We also added a coat

of a water based ablative anti foul paint over the CopperPoxy. We

felt that this would do some protection as we traveled into Mexico

and when it had been warn away, it would then re-expose the

CopperPoxy and it would then take over once again. Sort of a way to

lengthen the life.

Later

that month, we sailed out under the Golden Gate Bridge, turned left

and started our cruising life.

In 2007, we determined that the CopperPoxy was no longer effective

and decided to haul and do a bottom job.

We

remember the CopperPoxy as a VERY heavy, weight wise, coating and we

were not sure of putting another coat over the first. We were also

concerned about the buildup of layers of epoxy. And we were not sure

if we could get more of the product and get it to La Paz (where we

had the boat at that time) in time to do the bottom job and head back

out as we planned to do. So, in preparation for this we got 2 gallons

of Pettit Ultima SR in red. I (Greg) was doing a delivery of a power

boat from the San Francisco Bay area to La Paz, so getting the Pettit

back down to La Paz was easy.

Guenevere

was hauled in May of 2007 and the yard started a through pressure

wash.

| Guenevere

was hauled in

May of 2007 and the yard

started a through pressure

wash. |

|

It was obvious that some areas were starting to have hard

growth. As the pressure wash was continued, that hard growth fell

away. Near the boot stripe, were we applied extra CopperPoxy, we

could start to see a bit of the bright metallic copper color coming

through. On the sides, where the CopperPoxy was the standard

thickness, or thin, the bottom of the boat, gel coat, started

showing.

Now

for the surprise! There was NO metal copper remaining in that area.

It had all leached out of the mix. And, an even bigger surprise, with

the 60% copper gone, all that remained was something like a sponge of

epoxy. As the high pressure water sprayer worked this remaining thin

epoxy sponge was also removed! What remained was the clean fair

bottom!

I

did not need to worry about an excessive buildup on our bottom!

(hindsight is grand)

We

had an uneventful haul out and applied ALL 2 gallons (a lot for a 27

foot boat) of the Pettit. We then went into the Sea of Cortes. Within

2 months, we had hard growth all over the Pettit! All during the

summer I had to clean the bottom every 2 months or so.

On

our next haul out we plan to procure a substitute for the CopperPoxy

and reapply that!

Greg & Jill

|